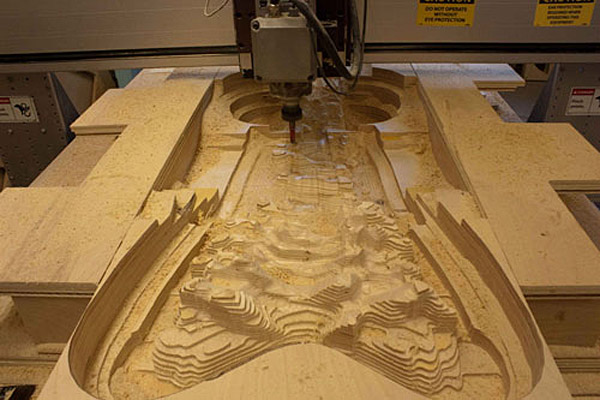

The Exocarp Chair is made using algorithmic design and a 3-axis CNC mill on three sheets of birch plywood. The results show incredible amounts of texture and dimension without even having to touch it. The design separates the surface areas by making the parts that the body touches really smooth and the parts that are on the outside, or away from the skin, are textured or irregular.

Description from the artist:

I have been fascinated for the longest time with reptiles skins and fruits with a tough skin. I find fascinating the duality and poetics that are involved in such complex systems; the way that they perform and look is primarily functional… Some scales may be modified for specialized functions, such as protective spines. This notion of function vs rough beauty is something that I find highly intriguing, so I started to play with the idea of creating objects closer to the human scale that deal with the same system… The design of Exocarp came about by separating the areas where the body would touch the chair and areas where an extrinsic agent might try to approach the chair. Thus, the areas that the user touches the chair became smooth and comfortable whereas the areas approached by an extrinsic agent became texturized using a script that uses a perlin noise algorithm to generate the irregular texture, where the script to generate the irregular texture increases in amplitude proportionate to the surface area. Through the use of birch plywood, a secondary pattern emerged through the variation of grain. This pattern was not really predicted and it was truly a wonderful surprise that can only be achieved by the use of CNC machines. This type of investigation starts to give more of an understanding of material and craftsmanship, as opposed to simply generating an output from a file; by layering the material and paying close attention to detail, a more personal product can be achieved through digital means, as opposed to a generic and utilitarian form.